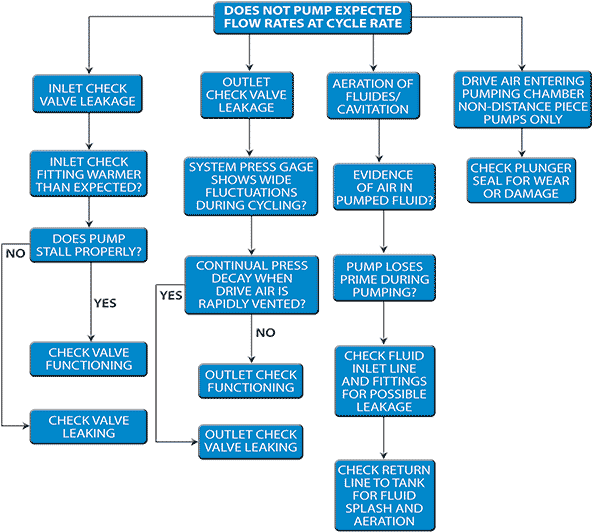

Does Not Pump Expected Flow Rates at Cycle Rate

THEORY OF CAUSE:

Under normal operation of any positive displacement gas booster, the gas that enters the inlet check valve must either go out the outlet check valve into the system, or compress without generating sufficient pressure to unseat the outlet check valve (maximum compression ratio). However, there are a number of conditions that can cause this output to be less than expected.

Inlet check valve leakage will permit some of the gas to return to the gas supply line during the pressure stroke. The greater the leakage rate, the more significant and noticeable the effect on gas output flow. If the operation of the booster has been on-going for a significant time, there could be a noticeable temperature increase on the inlet fitting as compared to the supply line. This is caused by the compression heating of the gas, and the fact that the "heated" gas is travelling back and forth through the inlet check valve, along with the newly inhaled gas. Also, and easier method of detecting inlet check valve leakage (if piston seal leakage has been determined to be small), is to stall the booster against pressure and see how much time it takes to make another cycle. The check valve is not designed to be an absolute shutoff, but it should hold for at least a minute or more between cycles.

Outlet check valve leakage will permit system pressure to re-enter the gas barrel during the booster suction stroke, resulting in more of the stroke being required to lower the pressure to inlet conditions. This means that less gas is being permitted to enter the chamber on each stroke. Again, the effect is proportional to the magnitude of the check valve leakage. The easiest way of detecting this leakage, is to pressurize the system to the desired pressure, and rapidly vent the air drive pressure. Discount the inlet supply line and, with a small diameter clean rod, unseat the inlet ball check permitting the gas barrel to vent. If the outlet check valve is sealing properly, there will be no significant leakage once the barrel pressure has dissipated. The check valves are not designed to “hold” system pressure indefinitely, so there may be a slight evidence of leakage that would be insignificant for the time of a booster cycle. Gross leakage of the outlet check valve can prevent the booster from achieving its desired pressure, and the outlet pressure gage will experience a wide excursion of the needle with each cycle if the system volume or the line size is small liquefaction or “collapse” of the compressed gas is another possible cause of loss in transfer capability. This can occur if the gas being boosted is capable of liquefying at the temperature and pressure generated. When this happens, the volume of the inhaled gas suddenly becomes a small fraction of what it was in order to liquefy, and there is no more compression to increase pressure. Also, if all of the liquid does not go through the check valves, it gives the effect of a substantial increase in unswept volume. This is because the residual liquid will vaporize on the suction stroke, and it will be difficult, if not impossible, to reduce the pressure below the supply pressure.

For this condition, pre-heating of the gas to above the critical temperature prior to boosting will eliminate the “collapsing” effect. This phenomenon usually occurs with “liquifyable” gases such as carbon dioxide, Freon, SF-6, etc.