External Leakage

EXTERNAL LEAKAGE:

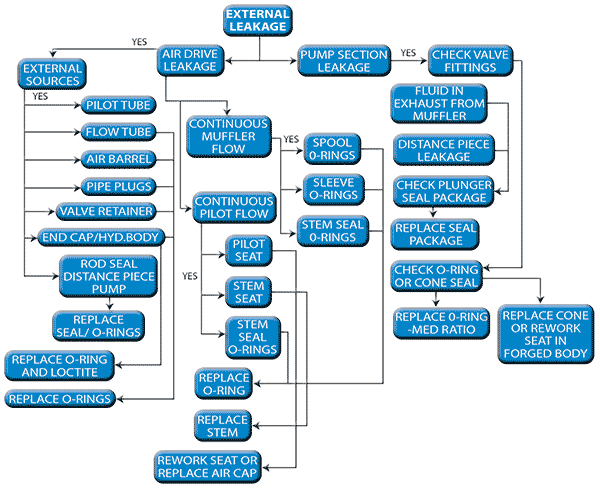

External leakage is always the result of a defective seal, and can be from the air drive (air or gas leakage), or the fluid section (oil, water, chemical fluids, etc.) leakage. This can cause operational as well as sanitary, corrosive, and toxic problems, depending on the application. In general, external leakage of pumped fluid is unacceptable, and must be corrected. External leakage of the air drive may be symptomatic of a condition that could result in a later problem. If the pump is to be driven by "sour gas", then it can be a toxic hazard. In that application, all normal vent ports are piped together and routed to a safe disposal area.

AIR DRIVE LEAKAGE:

Air drive leakage can be detected by the use of "bubble soap" or audible noise if the flow is large enough. "Cyclic" venting through the mufflers and pilot vent port is a "normal" condition for a "standard" pump, and is not a concern unless it becomes "continuous". For pumps with the severe service cycling modification, there will be some continuous venting from the mufflers. The following sequence should be used to determine the location of the leakage.

If leakage is audible, it is most likely large enough to be located by "feel" of the air flow coming from the leak. If there is no "audible" leakage, then bubble soap should be used for locating the suspected leak point. The possible areas to check include:

a. Pilot tube "O" rings

b. Flow tube "O" rings

c. Air barrel "O" rings (at end caps)

d. Pipe plug (1/2 inch) on lower cap sealing pilot chamber.

e. Valve retainer at exhaust end of cycling valve.

f. Connection of hydraulic section to air drive valve end cap. For "distance piece" pumps, leakage out of the rod seal or body seal of the distance piece.

g. Continual flow (in addition to the normal cyclic flow from the mufflers) can be caused by spool "O" ring damage, Sleeve "O" ring damage, or air drive piston "O" ring leakage, and will require some dis-assembly to determine exact cause.

h. Continual flow (in addition to the normal cyclic flow) from the pilot vent on the upper cap can be caused by pilot seat damage in the upper cap, damage to the pilot stem molded rubber insert, leakage of the stem seal "O" ring, or contamination on the seating surface.

FLUID SECTION LEAKAGE:

Fluid section leakage is normally easy to detect, since most of the pumped fluids are not volatile enough to evaporate rapidly. Because of the "wetting" action of most fluids, the plunger will normally have a very slight film when it emerges from the seal package. When the plunger enters the seal again, it has a tendency to "wipe off" the residue. Over an extended period of time, with a non-evaporating fluid, a slight build-up of fluid can occur in the distance piece versions of the pump. In the non-distance piece versions, the slight amount of seepage does not accumulate, since it is entrained in the exhaust of the lower air drive chamber. This is normal, unless the accumulation builds up in a relatively short operating time.

If the seal is actually leaking, there will be a noticeable build-up in the distance piece area, or a detectable amount of fluid in the exhaust air from the drive in the non-distance piece version.

In either condition, the plunger seal package should be replaced after it has been determined that there is no damage to the sealing surfaces of the plunger or the hydraulic body. Also, visually inspect to determine if contamination from the pumped fluid could have damaged the seal.

For external leakage in the area of the inlet and outlet check valves, the leakage will be visible around the retaining nut (for medium and high ratio pumps). For the medium ratio pumps, check the "O" ring seal on the check cartridge. For the high ratio pumps, verify that the retaining nut is tight enough, since the seal is made with metal to metal contact of a "cone" type seal that requires high contact pressure for proper function. Damage or contamination build-up in either case could require re-surfacing of the cone seal and seat, or replacement of the "O" ring and back-ups.

See flow chart for a quick overview of all trouble-shooting sequences.